Thermiculite® 866 is specifically designed for use as an electrically isolating, compression sealing material for SOFC and SOE applications, and has been used very successfully in a range of market-ready applications around the world.

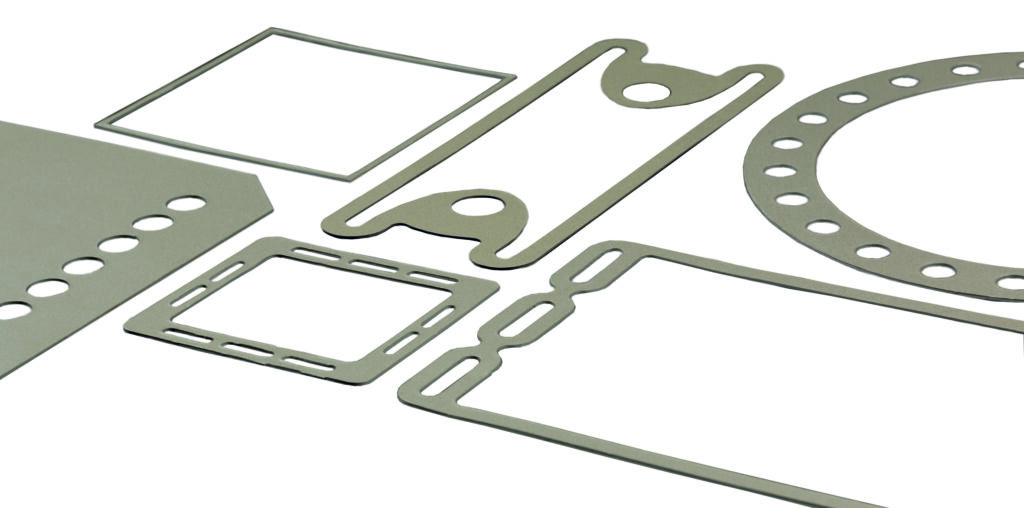

Our materials can be supplied in a range of thicknesses between 0.3mm and 1.0mm and cut seals to suit your stack design and can be provided with additional glass or anti-stick coating to further enhance their properties.

TH866 utilizes the unique properties of Thermiculite® technology, developed by Flexitallic based upon the use of chemically exfoliated vermiculite, to produce a range of high-performance, high-temperature resistant, electrically insulating, patented sealing materials.

Thermiculite® 866 needs a minimum of 3 to 5 MPa gasket stress to achieve an acceptable seal. For applications with lower loads we recommend Thermiculite 870

- Thermiculite®866 ensures that a seal is created and maintained in service

- No burn-off of organic material at elevated temperature

- No reduction in gasket thickness at elevated temperature

- Sealing performance not reduced by thermal cycling